Keep Your Cold Chain Compliant, Connected, and Under Control

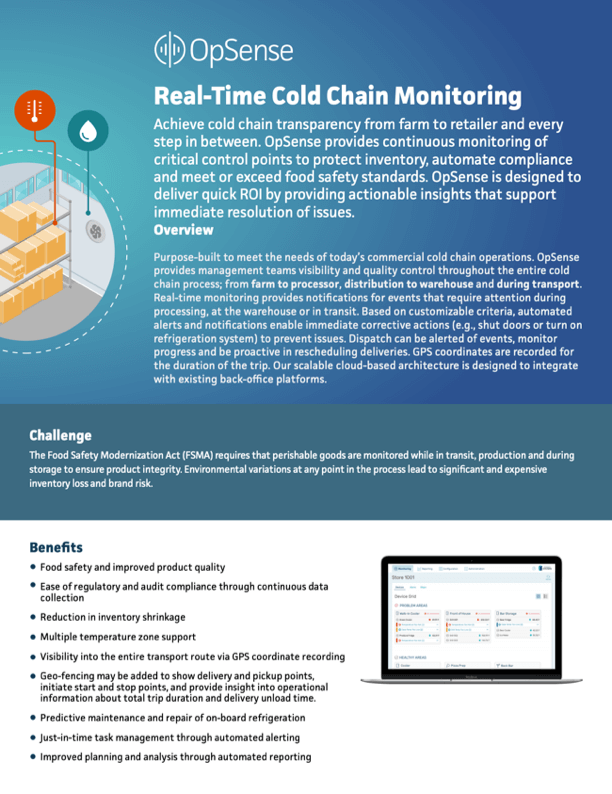

OpSense gives management teams complete visibility and quality control across the entire cold chain—from farm to processor, distribution to warehouse, and all the way to delivery.

Stay compliant with FSMA requirements by tracking temperatures, locations, and cold storage environments in real time. Customizable criteria trigger automated alerts and notifications, empowering your team to take immediate corrective actions and prevent costly issues before they happen.

With OpSense, your team can monitor events as they unfold, proactively reschedule deliveries, and ensure a smooth supply chain. GPS tracking captures every stop and movement throughout the journey, giving you a complete record for peace of mind.

Our scalable, cloud-based platform integrates seamlessly with your existing back-office systems, making it easy to implement without disrupting your operations.