Buddy's Kitchen, based in Burnsville, MN leads the industry in the customization of frozen food and co-packing. They operate two production facilities with close to 160,000 sq ft of space that deliver more than 350,000 meals daily.

Tom Webber is the VP of Food Safety at Buddy's Kitchen, overseeing food safety, quality assurance and regulatory compliance. Tom’s top priorities are managing compliance with customer requirements and keeping food safe through ever changing environments.

Prior to installing OpSense, Buddy's Kitchen had a remote temperature monitoring system that was cumbersome and failed quite often. Connectivity was a big problem as they lost connections frequently. Tom knew they needed to use technology, but their only experience had been a terrible one. Having technology that cannot be trusted or relied on meant they had to resort to manual documentation of every cold room temperature recorded on a piece of paper, twice per day, and managing the paper records throughout the year. That led to some compliance challenges.

If an employee went on vacation or changed jobs, the records would sometimes get missed. Occasionally there were issues with employees documenting an out of compliance temperature and not notifying anyone to fix the problem. Additionally, if there was a power outage over a weekend, Tom’s team would find out the refrigeration wasn’t working on Monday morning. These challenges would manifest in compliance audit scores.

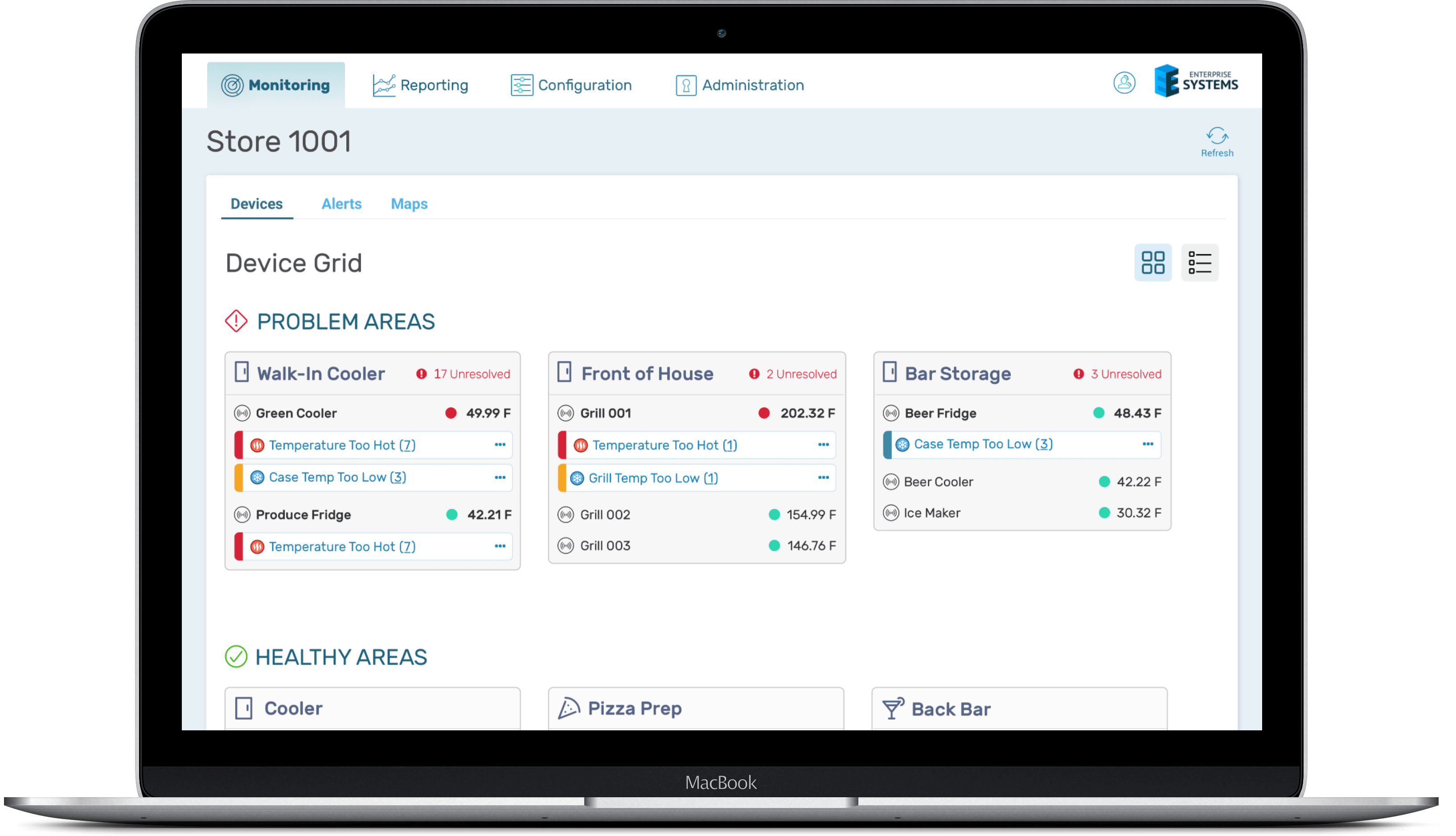

Tom saw results instantly after installing OpSense. As soon as he knew about the technology, and how economically feasible it was to implement he knew it was the right thing for Buddy's Kitchen. They now have electronic records at their fingertips, and can see real time situations remotely. OpSense helped visualize trending information on equipment starting to fail before it was too late. The old way of monitoring would not have been able to do that.

Tom describes success in his role as peaceful. "It's when everything is quiet and nothing is happening. When one works in a world of prevention, you are successful, when you are preventing issues from occurring."

“The software is powerful and easy to navigate. The support is remarkable.”

Tom Webber

Vice President of Food Safety and

Quality

Round-the-clock monitoring helps your distribution center meet food safety guidelines such as HACCP and FSMA consistently, rather than costly and error-prone manual observation. OpSense delivers quick ROI while providing actionable insights that increase food safety and staff efficiency.

Designed to meet the needs of today's high volume distribution centers, OpSense gives management teams visibility and quality control. The wireless sensor network can monitor temperature, humidity, open doors, leak and motion detection and energy for a true 360-degree view of your business. OpSense supports industry-leading protocols, including Bluetooth, LoRa, and Zigbee. Existing or client-preferred sensors may be incorporated so long as they align to standard industry protocols. Our scalable cloud-based architecture is designed to integrate with existing back-office platforms.