Yankee Trader Seafood, located in Pembroke, MA is family owned and operated and well-known for fresh ingredients with classic home-cooked flavors. Their hand-made seafood products are sold in over 4,000 stores and on QVC. Yankee Trader Seafood has a rich history of environmental impact initiatives. Their goals included improving energy efficiency, reducing waste and minimizing their carbon footprint. When Yankee Trader Seafood outgrew their distribution facility in 2019, they decided it was the perfect time to upgrade their food safety data collection capabilities. Since manual operations monitoring is a time-consuming process that is frequently vulnerable to human error, they selected OpSense so they could be confident that the temperatures in their food storage areas were accurate and auditable.

Weeks after installing sensors and implementing the OpSense platform, the temperature on a cooler was inadvertently set incorrectly. When the temperature fell out of the established range, alerts notified the appropriate personnel and the issue was resolved, saving thousands of dollars of seafood products.

Compliance requires consistent and accurate data collection. Wireless sensors placed in walk-ins, coolers and freezers, make the process accurate and efficient. Yankee Trader Seafood now has around the clock data collection and confidence that the temperatures in their food storage areas are accurate and auditable 24/7/365. The detailed reporting from OpSense makes it simple to verify quality and prove compliance during audits - leading to their best SQF and FDA audits ever.

“We just wrapped up a 3 day audit this morning…It went great! The auditor was impressed with the OpSense system, after seeing the data it made some of our HACCP Steps an easy checkmark. We love it. Thank you for all your help.”

Alex Hernan

Executive VP of Operations

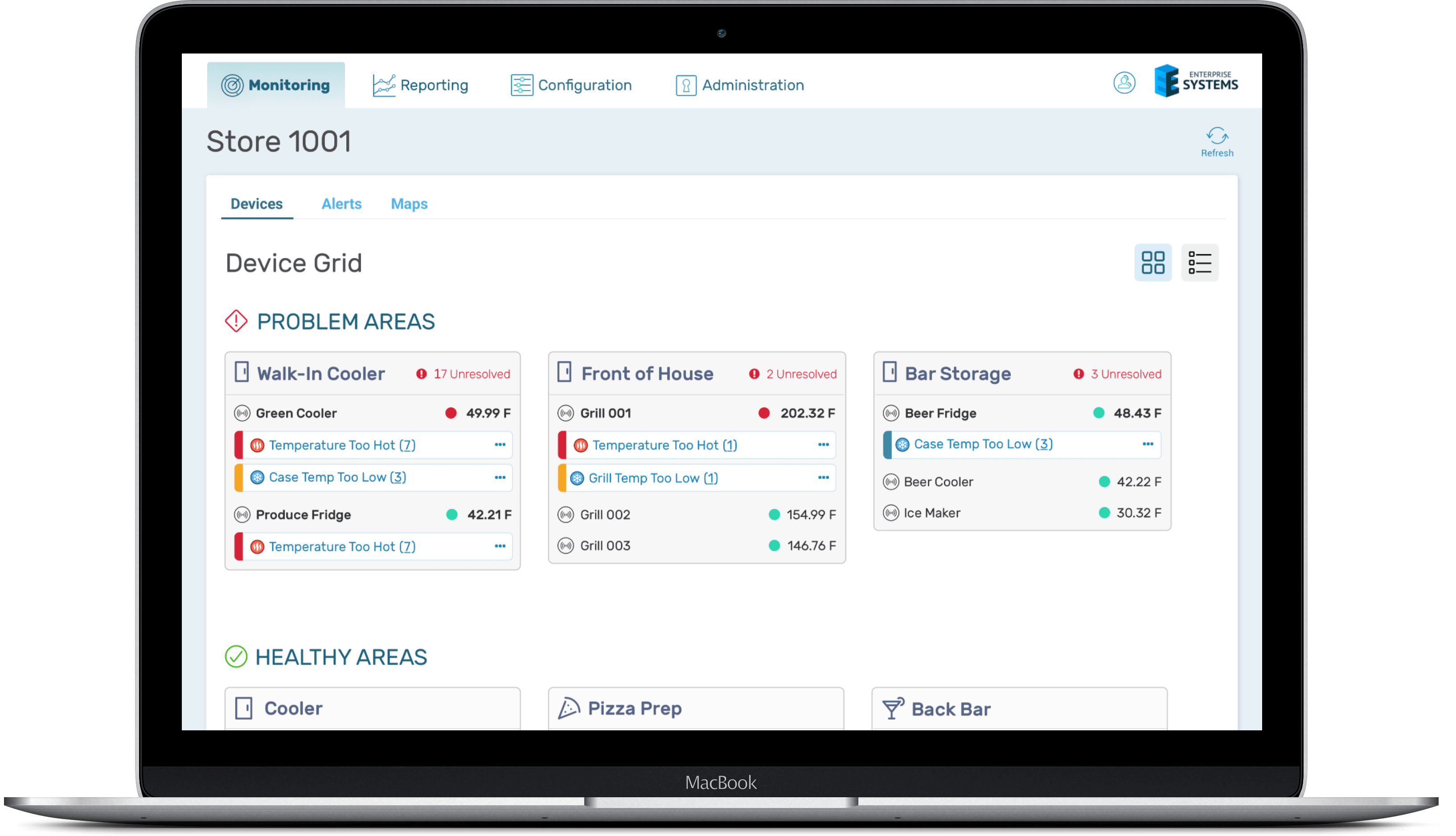

Around-the-clock monitoring provides your production facility with visibility that helps you meet or exceed food safety requirements, prevent inventory loss, and improve refrigeration efficiency. Achieve quick ROI with actionable insights that increase food safety and staff efficiency.

Designed to meet the needs of today’s high volume production facilities, OpSense gives management teams visibility into their operations and an additional way to maintain high quality standards. The wireless sensor network can monitor temperature, humidity, open doors, HVAC conditions, lighting, sound, weight, voltage, and other critical operations such as task management, checklists, equipment, and energy costs for a true 360-degree view of your business. If there is an issue, you and your team can receive alert notifications via custom emails, text messages and/or phone calls before it affects the bottom line. As a software company, OpSense uses the best hardware for the job and supports industry-leading protocols including Bluetooth, LoRa, and Zigbee. The scalable cloud-based architecture is designed to integrate with existing back-office platforms.