Remote temperature monitoring for hospitality operators

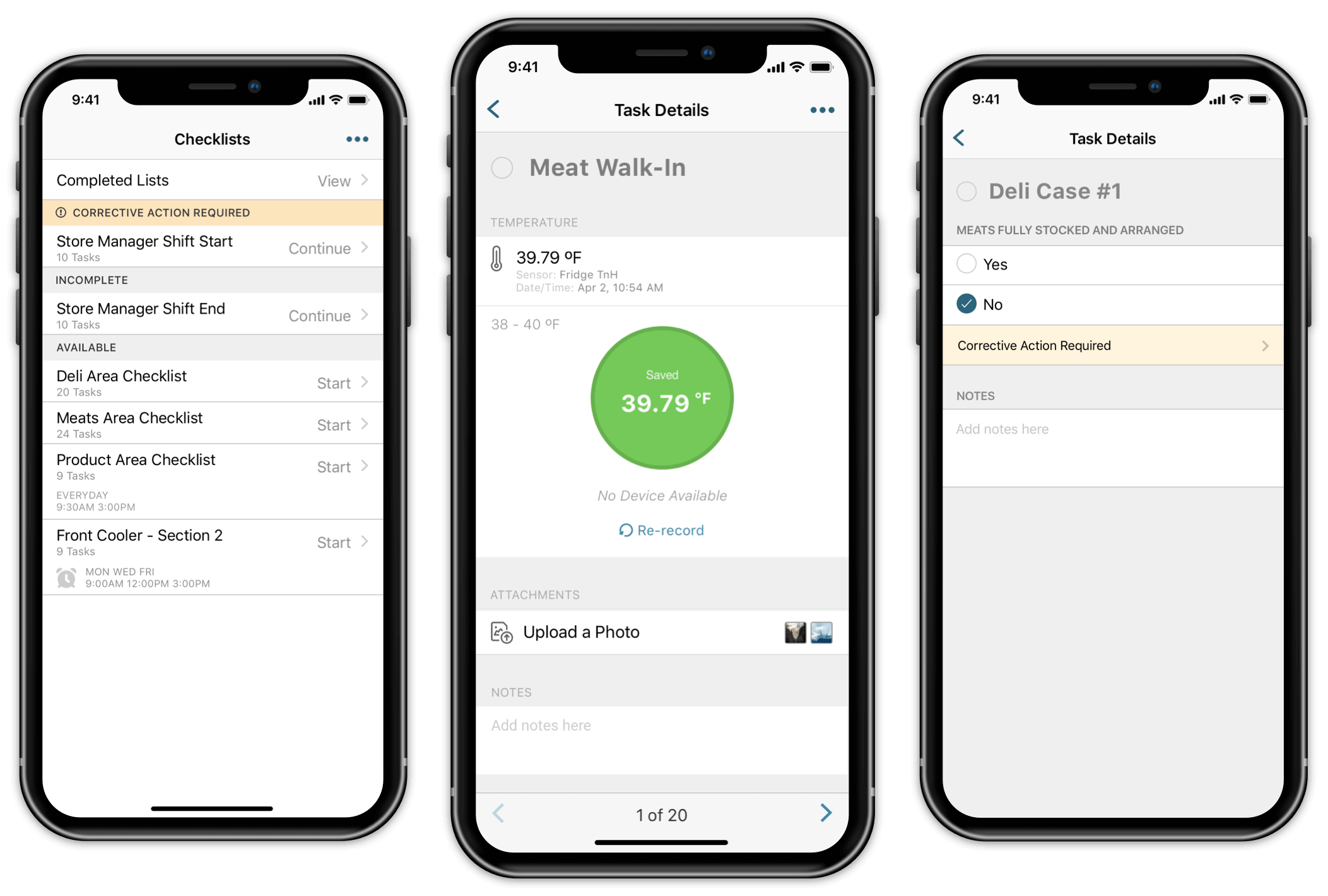

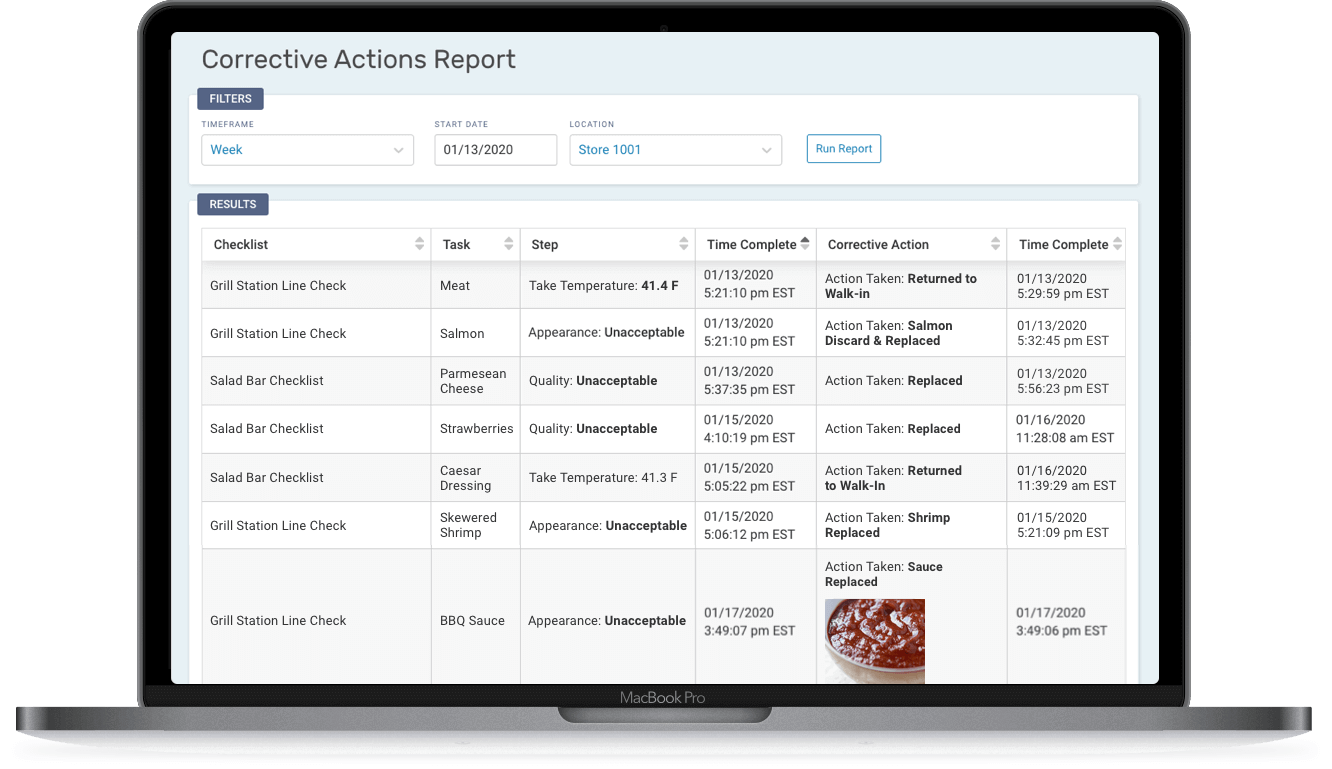

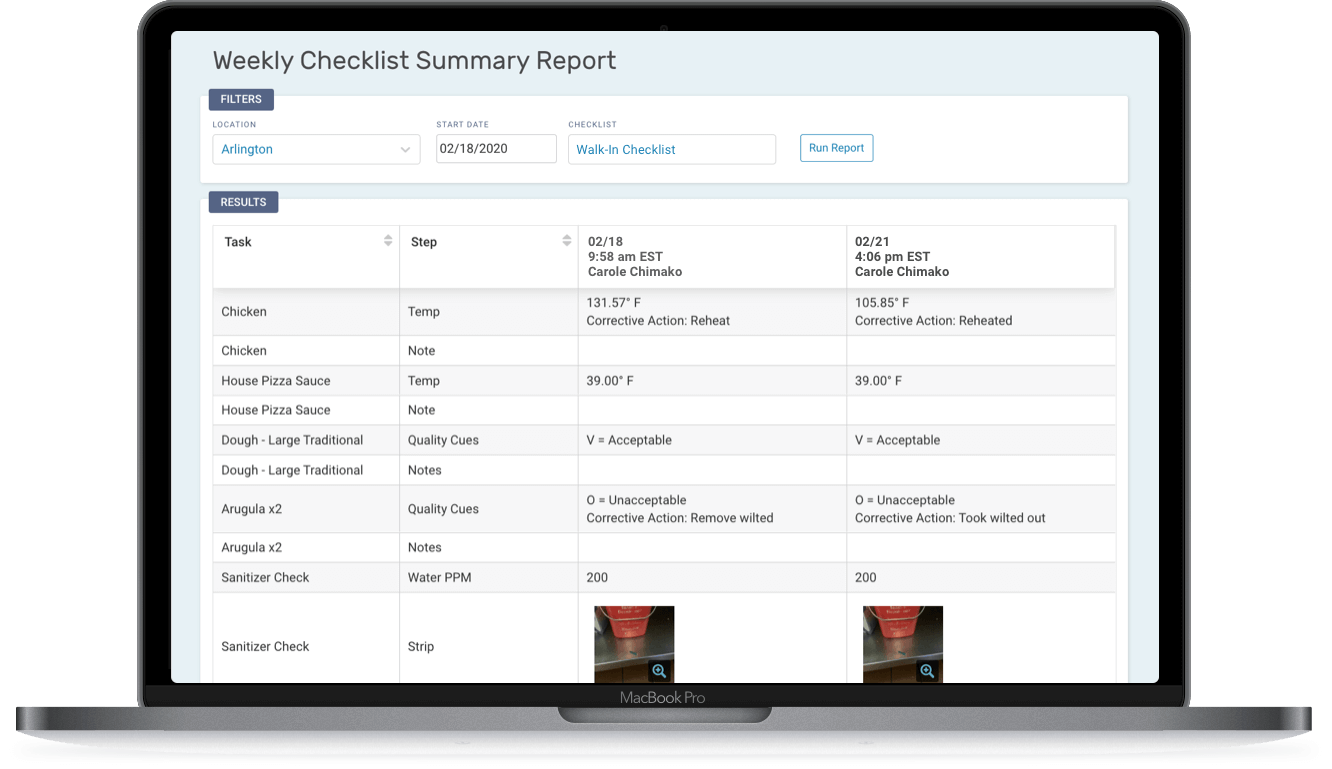

Refrigeration malfunctions lead to significant and expensive inventory loss and high profile food safety events. Manual operations monitoring is a time-consuming process that is frequently vulnerable to human error. Automating food safety saves time, saves money and creates efficiencies. Around-the-clock data collection helps your operation meet HACCP and FSMA guidelines consistently, so you’ll always be ready for the next compliance audit. Remotely track temperatures in freezers and coolers, energy usage, HVAC conditions, and more. OpSense provides visibility into all locations to see at a quick glance that all critical control points are safe. Most locations achieve ROI within months.